Industrial spiral freezing and cooling systems

Some of our clients...

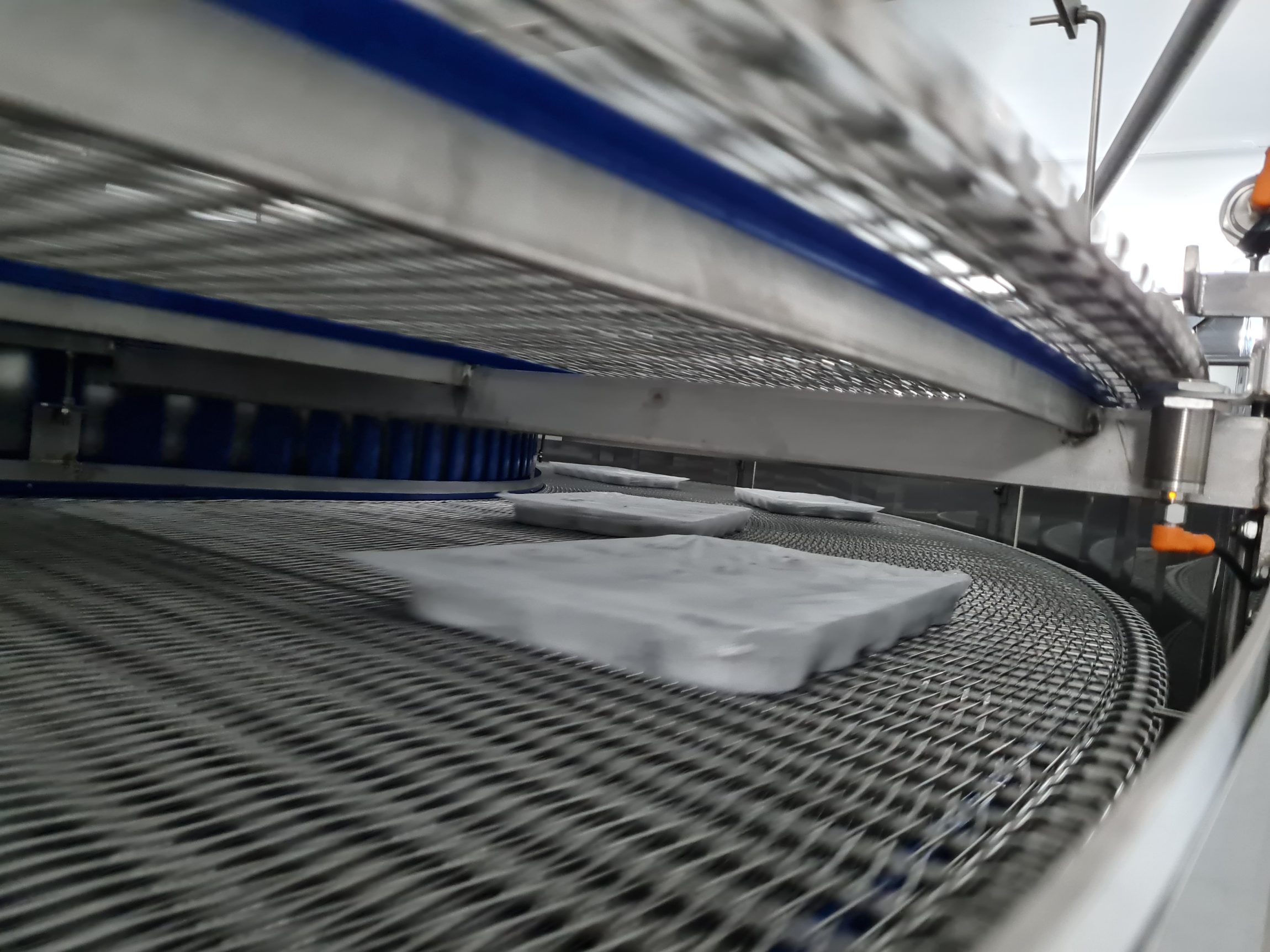

Spiral freezers

Spiral Freezers are complex and essential pieces of machinery that are built specifically for food manufacturers to meet production requirements.

While many businesses might still be using Cold Room Blast Freezers, Spiral Freezers have taken the evolution of food manufacturing to the next stage.

Now, of course, both Cold Room Blast Freezers and Spiral Freezers do broadly the same job – freezing food products quickly and effectively so they’re ready for storage and transportation.

But it’s about HOW the job is done and how efficient it is.

How effective are spiral freezers?

At Korutek, we understand the importance of efficiency, delivering for your customers, and optimising your freezing technology for the space you have and the needs of your business.

It’s why we know that Compact Spiral Freezers can improve your food production in almost every aspect, including:

Maximising the space that you have to work in

Maximising the space that you have to work in

Precise specification & design

The idea of spiral freezers is to design and optimise the built so that it’s a long-term asset for global food manufacturers, nationwide food manufacturers, and even small and medium-sized food manufacturers.

Ensuring the design is to the precise specifications you require is essential, though.

It’s why we pride ourselves on our decades of experience working with the food manufacturing sector to provide engineering and technical solutions, designs, installations, maintenance, and repair work.

Because having the highest level of technical proficiency and expertise available to you to install, maintain, and inspect your spiral freezing technology can prolong your system’s lifespan and keep you producing top-quality products on time year after year.

Why spiral freezers?

Knowing where to begin with spiral freezers might be easier said than done but fear not… we’re here to help.

Our Compact Spiral Series works with a ‘plug-in and operate’ solution to remove heat from your food manufacturing process as well as increase productivity, reduce your costs, improve (and maintain) product quality, and maximise your factory floorspace.

It’s suitable for cooling, chilling OR freezing products such as;

- Raw meat

- Poultry

- Fish

- Baked, cooked, and fried products

- Ready meals

- Soups

- Ice creams

- Desserts

- And pet foods

Benefits of spiral freezing

Replacing an old spiral system or moving from a labour-intensive and inefficient static blast freezer can feel like a big commitment, but it doesn’t need to be.

Our machines are fully automated, which means you can operate continuous production and reduce the cost per unit of frozen and chilled products as well as improve both the quality AND consistency of your products, even after defrost!

The Compact Spiral Series works by blowing cold air over the products to remove the heat quickly and efficiently by freezing and cooling quickly. It also means that the ice crystals that are frozen in products are smaller, leading to higher quality foods at the point they’re frozen or chilled because it works while they’re at their freshest…

Smaller ice crystals allow the product to keep its shape, colour, smell and taste after defrosting, to a far greater extent. Meaning products maintain their cellular structure, consistency and therefore quality.

Which means you’re locking in peak nutritional value time after time, so the end consumer receives an even better product.

New spiral freezer systems for global manufacturers

Spiral freezers need to be designed and built optimally to be appropriate assets for global food manufacturers.

However, a lack of technical expertise in the design and irregular servicing could compromise the system’s lifespan causing costly outages.

Whether you have an existing machine or are considering a new build, Korutek Engineering are the international spiral freezer specialists to turn to.

We operate not only from a position of total professionalism, but of transparency.

Following a detailed assessment of your needs, we provide detailed breakdowns of any work required.

In the case of servicing and maintenance, this includes categorised recommendations, helping you gain a greater understanding of your machine.

Korutek Engineering Systems

Korutek build spiral freezers and chillers for the biggest food manufacturers around the world. If you’re looking for a team with a global reach that is able to provide industry-leading design and build services, contact Korutek today.

Compact Spiral Series

The Compact Spiral Series, consists of the 300 (CPS300), 450 (CPS450) and the 600 (CPS600) models.

Compact Inline Tunnel

The system operates as one system using one, two or three separate inverter-controlled conveyor belts.

Spiral freezer systems

We are new system specialists, operating and consulting with the largest food industry manufacturers, all over the world.

Spiral chiller systems

Korutek Engineering are new spiral chiller specialists, operating and consulting with the largest food industry manufacturers.

Spiral cooler systems

We are new spiral cooler system specialists, manufacturing for and consulting with global food industry companies.

IQF freezers

We are an IQF freezer specialist, operating and consulting with some of the largest food manufacturers across the world.

Freezer Leasing Solutions

Revolutionise Your Food Production with Korutek's Freezer Leasing Solutions.