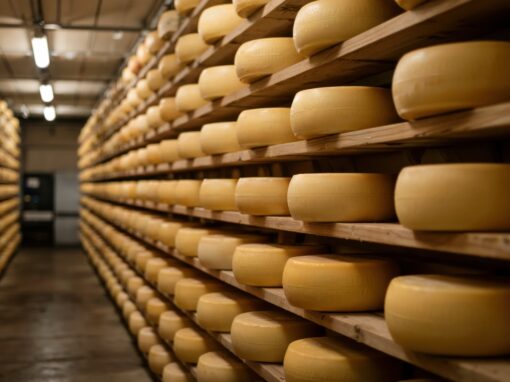

Cheese Manufacturing Client

A leading cheese manufacturer with a history of innovation and global presence has long been recognised for its pioneering spirit and commitment to quality. Known for introducing spreadable cheese products early in the 20th century, the company continues to expand operations across multiple countries.

What sets this manufacturer apart is its strong focus on social responsibility, with profits directed toward supporting humanitarian efforts, scientific research, and environmental initiatives.

When the company encountered a technical challenge with their spiral freezer, they sought a solution that matched their high standards of efficiency and reliability.

Korutek’s Approach: Expertise in Action

Site Inspection & Planning

Korutek’s engineers carried out a detailed inspection to assess the extent of misalignment and wear. Every detail was measured meticulously to ensure the proposed solution was precise and practical.

Proposal & Timeline Presentation

Proposal & Timeline Presentation

A clear plan was presented, outlining the scope of work, anticipated challenges, and an exact timeline. The objective was to complete the repair with minimal disruption to production.

Execution & Hard Work

Execution & Hard Work

The replacement of the drum support rings required impeccable accuracy. Korutek’s engineers executed the task with precision, ensuring every component was aligned perfectly.

Completion & Quality Assurance

Completion & Quality Assurance

After the repair, the spiral freezer underwent thorough testing. The results were immediate—restored functionality and improved operational efficiency.

Precision Repair & Excellence –

Korutek’s Work on a Cheese Manufacturer’s Spiral Freezer

The Facilities Manager shared his feedback following the repair. When asked to rate the timeliness and quality of the work, he responded with a 10 out of 10, stating:

“The whole process, from measuring, proposal, presenting timeline, to attending site and completing the works, was efficient and well-planned. The timeline was predicted and stuck to for the duration of the work. The quality of the repair seems to be excellent. I do not foresee any reason to doubt that it will last for many years.”

Regarding the spiral freezer’s performance post-repair, he noted:

“Since the repair, we have not had a single fault indicated on the spiral after a week of normal running. This was the main target, but as a consequence, the spiral seems to be much smoother and quieter.”

The Challenge: A Spiral Freezer in Need of Expertise

For years, the spiral freezer had operated smoothly, ensuring uninterrupted production. However, as with any mechanical system, natural wear and tear eventually took its toll. The drum support rings became misaligned, leading to a bulged and twisted structure that required immediate attention.

This was no routine fix. The repair demanded precise measurements and execution, making it a highly specialised job. Many providers either couldn’t take on the challenge or offered lengthy lead times, leaving the manufacturer in need of a capable and reliable partner.

The Result: A Stronger Partnership

Korutek’s commitment to precision, efficiency, and customer satisfaction left a lasting impression. So much so that the manufacturer expressed interest in establishing a service maintenance agreement, ensuring their spiral freezer continues to operate at peak performance.

When asked how likely he was to recommend Korutek to others in the industry, the Facilities Manager once again rated the experience a 10 out of 10, commenting:

“I would certainly recommend Korutek to others. The quality/cost/efficiency of the work is as would be expected. The team was a pleasure to work with, keeping me well updated on progress and being courteous to other members of our team that they encountered.”

Conclusion: A Testament to Excellence

This cheese manufacturer’s dedication to quality and responsibility extends to every aspect of their operations. When faced with a complex repair, they sought a partner who could deliver with precision and reliability.

Korutek Engineering rose to the challenge, providing a repair that not only resolved the immediate issue but also strengthened the long-term partnership. The spiral freezer is now running more smoothly than ever, with improved efficiency and reliability.

A job well done, a satisfied customer, and a spiral freezer back at peak performance—this is what engineering excellence looks like.

Latest Case Studies