Spiral Chiller System Engineers

Some of our clients...

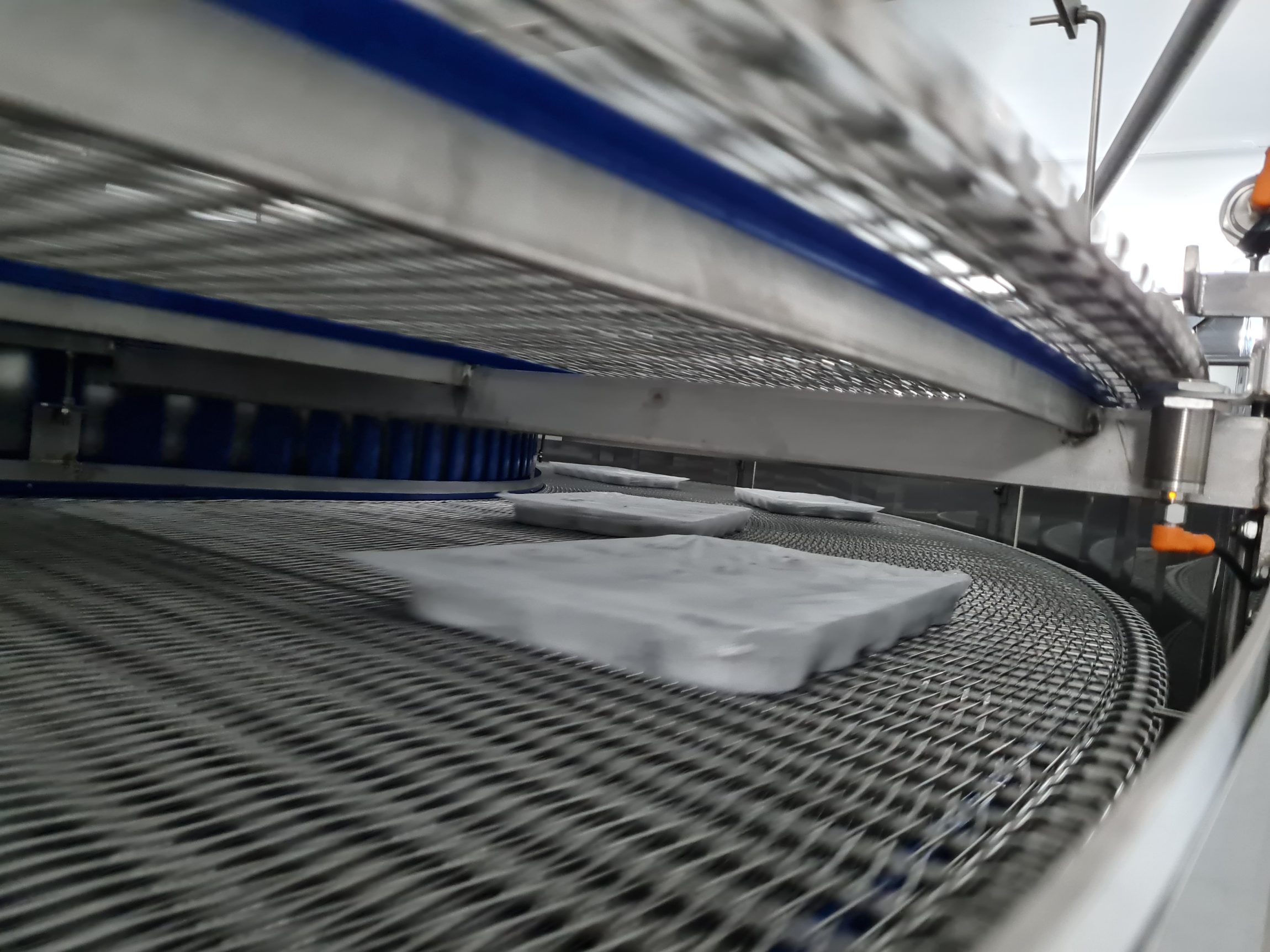

Spiral Chillers

Korutek Spiral Chillers are high-performance systems designed specifically for food manufacturers who require rapid and efficient chilling of their products.

Unlike conventional chilling methods, Korutek Spiral Chillers are engineered to optimize the chilling process, ensuring consistent quality and incorporating a hygienic design that meets rigorous cleanliness standards.

These systems are perfect for processing large volumes of food products such as meats, poultry, fish, baked/cooked/fried goods, soups, ice cream, desserts, pet food and ready meals.

The Spiral Chillers maintain a uniform temperature across all products, thereby preserving texture, flavour, and nutritional value while maintaining their quality.

How Effective Are Spiral Chillers?

Korutek’s Spiral Chillers are equipped with advanced technology that ensures maximum efficiency in the chilling process. By utilizing vertical space and automating operations, these systems reduce energy consumption and improve workflow. This efficiency translates to cost savings for manufacturers and ensures that products reach the desired temperature quickly, minimizing the risk of bacterial growth and spoilage.

The consistent cooling process provided by Spiral Chillers is crucial for maintaining the integrity of various products, including raw meats, baked goods, and frozen desserts.

Space Efficiency: Utilises vertical space, making it ideal for limited floor space.

Continuous Operation: Allows uninterrupted production, enhancing productivity.

Consistent Quality: Maintains product integrity by minimising temperature fluctuations.

Cost Efficiency: Reduces energy consumption and operational costs.

Precise specification & design

At Korutek, we understand that every production line has unique requirements. That’s why our Spiral Chillers are custom designed to fit the specific needs of your manufacturing process. Our engineering team works closely with you to ensure that every aspect of the system, from the conveyor design to the chilling capacity, is tailored to your operational demands. The result is a highly efficient, reliable, and durable chiller that enhances productivity and meets stringent food safety standards.

Why Choose Spiral Chillers?

When you choose Korutek’s Spiral Chillers, you are investing in a solution that combines innovation with practicality. Our chillers are designed to handle a wide range of food products, providing consistent chilling that preserves product quality. Whether you are processing delicate baked goods or robust meat products, our Spiral Chillers offer the versatility and reliability needed to maintain high standards. The systems are also designed for ease of maintenance, ensuring long-term operational efficiency. These chillers are ideal for industries requiring precise temperature control and continuous production without compromising efficiency.

Benefits of spiral chilling

Korutek Spiral Chillers provide numerous benefits that enhance your production capabilities. These systems are fully automated, reducing wastage, labour costs and increasing throughput. The efficient design minimizes energy consumption, which helps lower operational costs.

Additionally, the rapid chilling process ensures that products maintain their nutritional value, texture, and taste. This makes Spiral Chillers an indispensable part of any modern food production line, contributing to consistent product quality and safety.

New spiral freezer systems for global manufacturers

Spiral freezers need to be designed and built optimally to be appropriate assets for global food manufacturers.

However, a lack of technical expertise in the design and irregular servicing could compromise the system’s lifespan causing costly outages.

Whether you have an existing machine or are considering a new build, Korutek Engineering are the international spiral freezer specialists to turn to.

Following a detailed assessment of your needs, we provide detailed breakdowns of any work required.

In the case of servicing and maintenance, this includes categorised recommendations, helping you gain a greater understanding of your machine.

Spiral Chiller Questions

Korutek Engineering Systems

Korutek build spiral freezers and chillers for the biggest food manufacturers around the world. If you’re looking for a team with a global reach that is able to provide industry-leading design and build services, contact Korutek today.

Compact Spiral Series

The Compact Spiral Series, consists of the 300 (CPS300), 450 (CPS450) and the 600 (CPS600) models.

Compact Inline Tunnel

The system operates as one system using one, two or three separate inverter-controlled conveyor belts.

Spiral freezer systems

We are new system specialists, operating and consulting with the largest food industry manufacturers, all over the world.

Spiral chiller systems

Korutek Engineering are new spiral chiller specialists, operating and consulting with the largest food industry manufacturers.

Spiral cooler systems

We are new spiral cooler system specialists, manufacturing for and consulting with global food industry companies.

IQF freezers

We are an IQF freezer specialist, operating and consulting with some of the largest food manufacturers across the world.

Freezer Leasing Solutions

Revolutionise Your Food Production with Korutek's Freezer Leasing Solutions.