Korutek Remote Condition Monitoring

Predict Failures Before They Happen.

Protect Productivity.

Elevate Performance.

Remote Condition Monitoring of cooling, chilling and freezing machinery

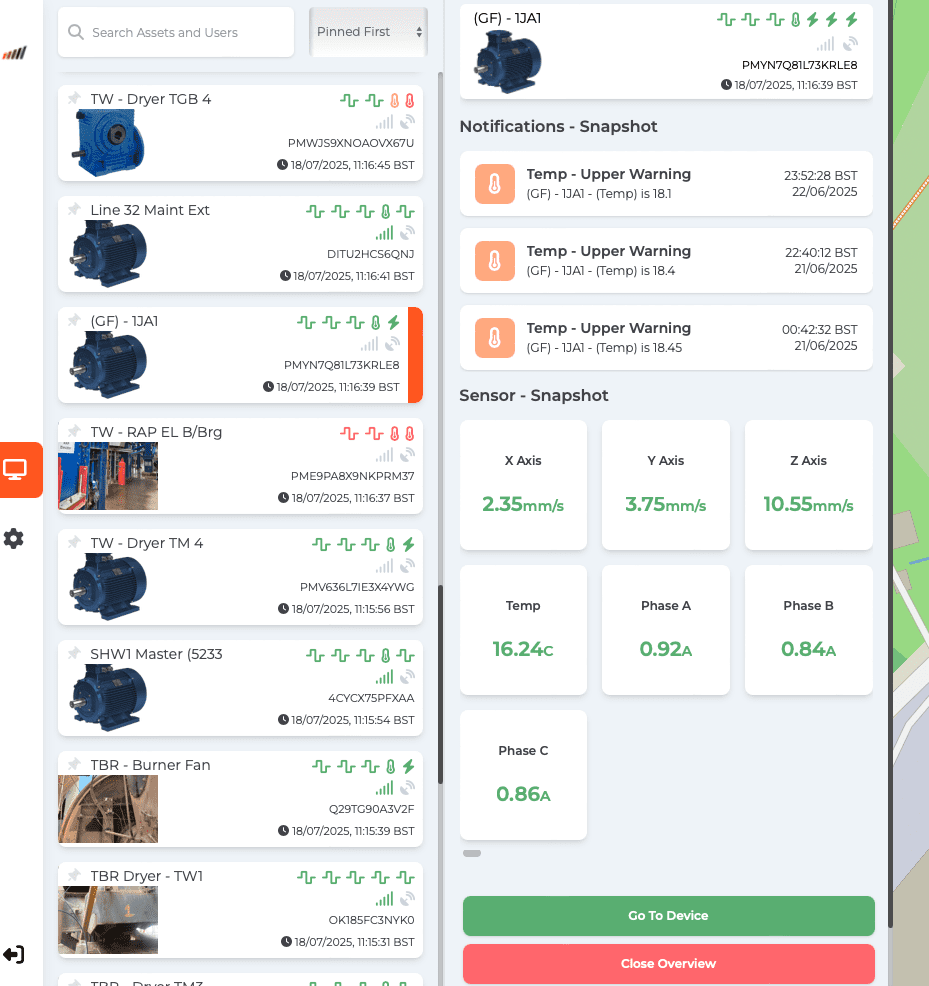

Monitor your Key Assets

Korutek Remote Condition Monitor helps engineering, maintenance and plant managers monitor spiral freezers and other key assets 24/7, enabling proactive maintenance and reduced downtime.

It empowers your team to respond swiftly and precisely when issues arise, ensuring operations remain efficient and unplanned downtime is kept to a minimum.

Always-on Monitoring Solution

As many industries face leaner maintenance teams, due to post-COVID workforce reductions and ongoing cost-cutting, Korutek Remote Condition Monitor steps in as a reliable, always-on monitoring solution. Make data-driven decisions, cut energy costs, make your production reliable and extend the life of your equipment.

Key Benefits

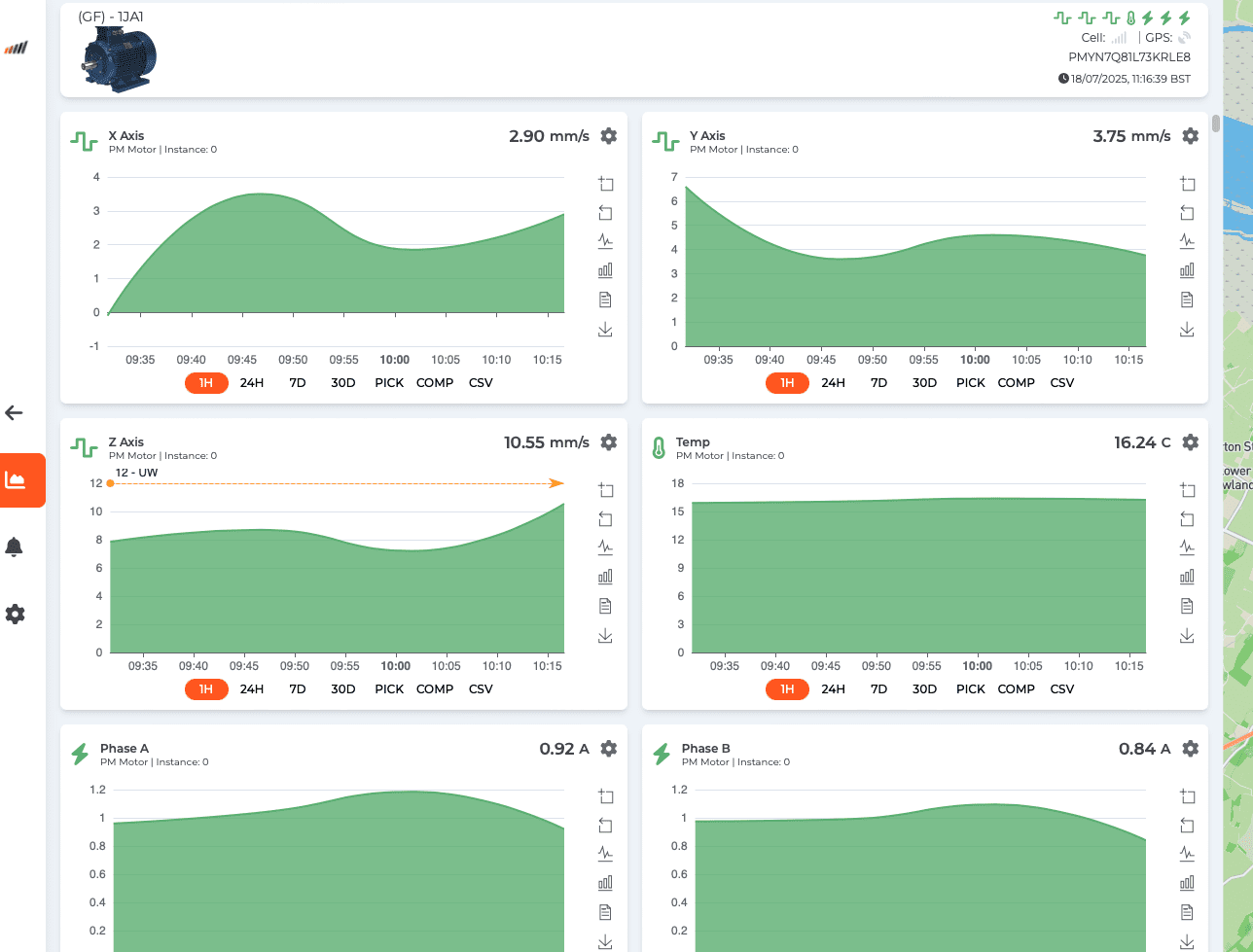

Real-Time Monitoring:

24/7 visibility into motor performance, vibration, temperature, and load.

Reduced Downtime:

Identify early signs of failure to schedule planned preventive maintenance instead of reacting to unexpected shutdowns.

Energy Efficiency:

Optimise motor loads to save energy and reduce CO₂ emissions.

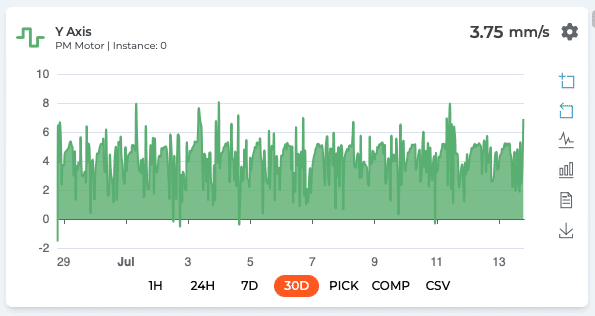

Intelligent Insights:

Data-backed alerts and trends to support smarter maintenance decisions.

Support Sustainability:

Helps clients meet Net Zero goals through reduced energy usage and extended asset life.

Korutek Remote Condition Monitoring

Features at a Glance

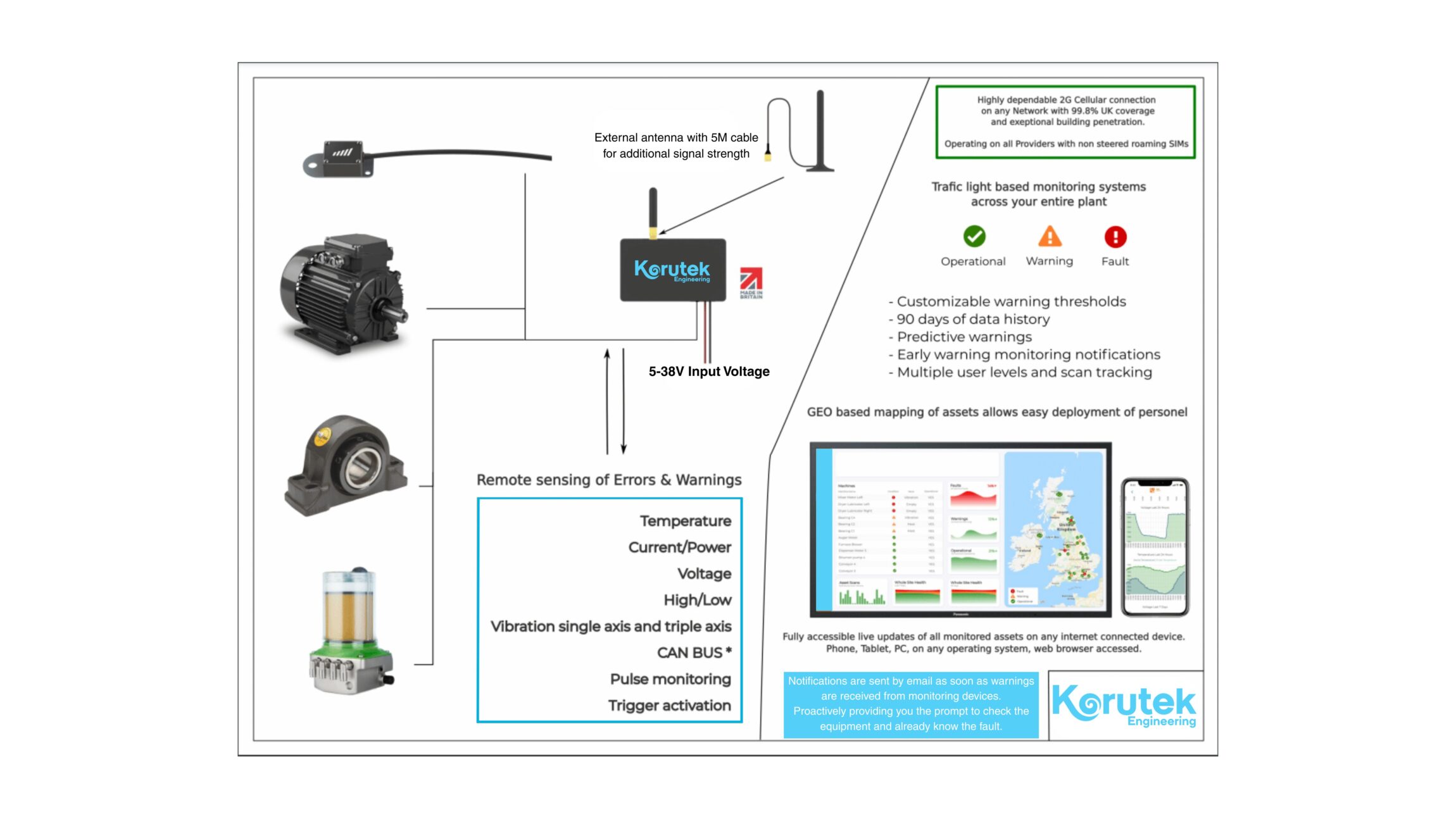

Feature: Motor, gearbox & bearing monitoring

Benefit: Prevent critical equipment failures

Feature: Vibration & temperature analysis

Benefit: Detect lubrication or alignment issues early

Feature: Load and current trace

Benefit: Reduce electricity bills and CO₂ footprint

Feature: Dashboard & alerts

Benefit: Intuitive visual data and automated notifications

Feature: Retrofit design

Benefit: Prevent critical equipment failures

Feature: Motor, gearbox & bearing monitoring

Benefit: Easy installation on existing equipment

Built for Today’s Industrial Challenges

Smart, Scalable, and Secure Monitoring—Anywhere

Korutek RCM is a complete remote condition monitoring solution designed for modern manufacturing and processing facilities.

A real-life example:

A 22kw motor ran at 35A instead of optimal 29.5A, costing £7,116 extra/year in energy. Remote Condition Monitor identified this inefficiency, allowing proactive adjustment and cost recovery.

Korutek Remote Condition Monitoring

Key Capabilities:

24/7 Monitoring

for motors, gearboxes, pumps, fans, bearings, and lubrication systems across any number of locations.

Custom Alerts & Reports:

Configure alarms for delays or anomalies ranging from seconds to days, so nothing is missed.

Simple Setup:

Fast in-house installation with a plug-and-play interface and intuitive online dashboard.

Real-Time Alerts:

Notifications are instantly sent to your laptop or mobile device when predefined performance thresholds are breached.

Cost-Effective:

Low-cost hardware and affordable data usage make advanced monitoring accessible.

Strong Connectivity:

Operates using low-frequency cellular signals for maximum building penetration and reliability in low-signal areas.

Flexible Connectivity Options:

LoRaWAN, WiFi, and Bluetooth compatibility to ensure robust signal strength and flexibility in sensor placement.

Centralised Asset Oversight:

Monitor entire systems using a central controller with additional wired or wireless (Bluetooth) sensors.

Korutek Remote Condition Monitoring

Modern Maintenance, Backed by Smart Data

Here’s how Korutek supports best-in-class food manufacturing machinery maintenance programs:

Preventive Maintenance (PM):

Schedule sensor-based tasks like lubrication, oil changes, or component inspections based on usage or wear.

Corrective Maintenance:

Catch anomalies via vibration, temperature, or current monitoring and dispatch repairs before breakdowns occur.

Predictive Maintenance (PdM):

Leverage Remote Condition Monitoring to predict failures just in time—reducing unplanned downtime and repair costs.

Hygiene Maintenance:

Ensure sanitation systems like CIP/COP are functioning properly; use sensors for compliance validation.

Work Order Management:

Alerts from Korutek can auto-generate CMMS work orders with asset ID, location, and fault type.

Fully Compatible with CMMS Systems

Korutek integrates seamlessly with leading Computerized Maintenance Management Systems (CMMS) like Limble, Fogwing, Fiix, UpKeep and other —enabling unified oversight of your operations.

Use Korutek data to enhance CMMS workflows:

- Trigger work orders automatically from sensor alerts

- Feed real-time data into preventive, predictive, or corrective maintenance

- Improve regulatory audit readiness (e.g., HACCP, FDA, BRCGS)

Sample Task Integration:

Tuesday: Preventive check on spiral freezer via Korutek RCM alert → Work order assigned in CMMS → Task completed & logged

Korutek Remote Condition Monitoring

Reach out today to explore how we can help.

+44 (0)1603 672 455

info@korutek.com

Korutek Engineering Ltd

Centrum, Norwich Research Park,

Norwich, NR4 7UG