Spiral System Modification

Optimising Performance, Increasing Efficiency

At Korutek Engineering, we understand that food production requirements evolve. Whether you need to increase throughput, adapt to new product lines, or improve energy efficiency, our Spiral System Modification services ensure your equipment aligns with your operational needs.

Why Modify Your Spiral System?

Enhance Production Capacity

Upgrade your system to handle higher throughput while maintaining product quality.

Improve Energy Efficiency

Implement advanced cooling and freezing technologies to reduce energy consumption.

Adapt to Product Changes

Modify belt widths, airflow systems, or control settings to accommodate new product types.

Extend Equipment Lifespan

Avoid costly replacements by optimising existing systems for continued reliability.

Our Modification Process

System Assessment & Consultation

We start with an in-depth inspection of your existing spiral system, identifying opportunities for improvement while considering your specific production requirements.

Customised Upgrades

Our modifications include:

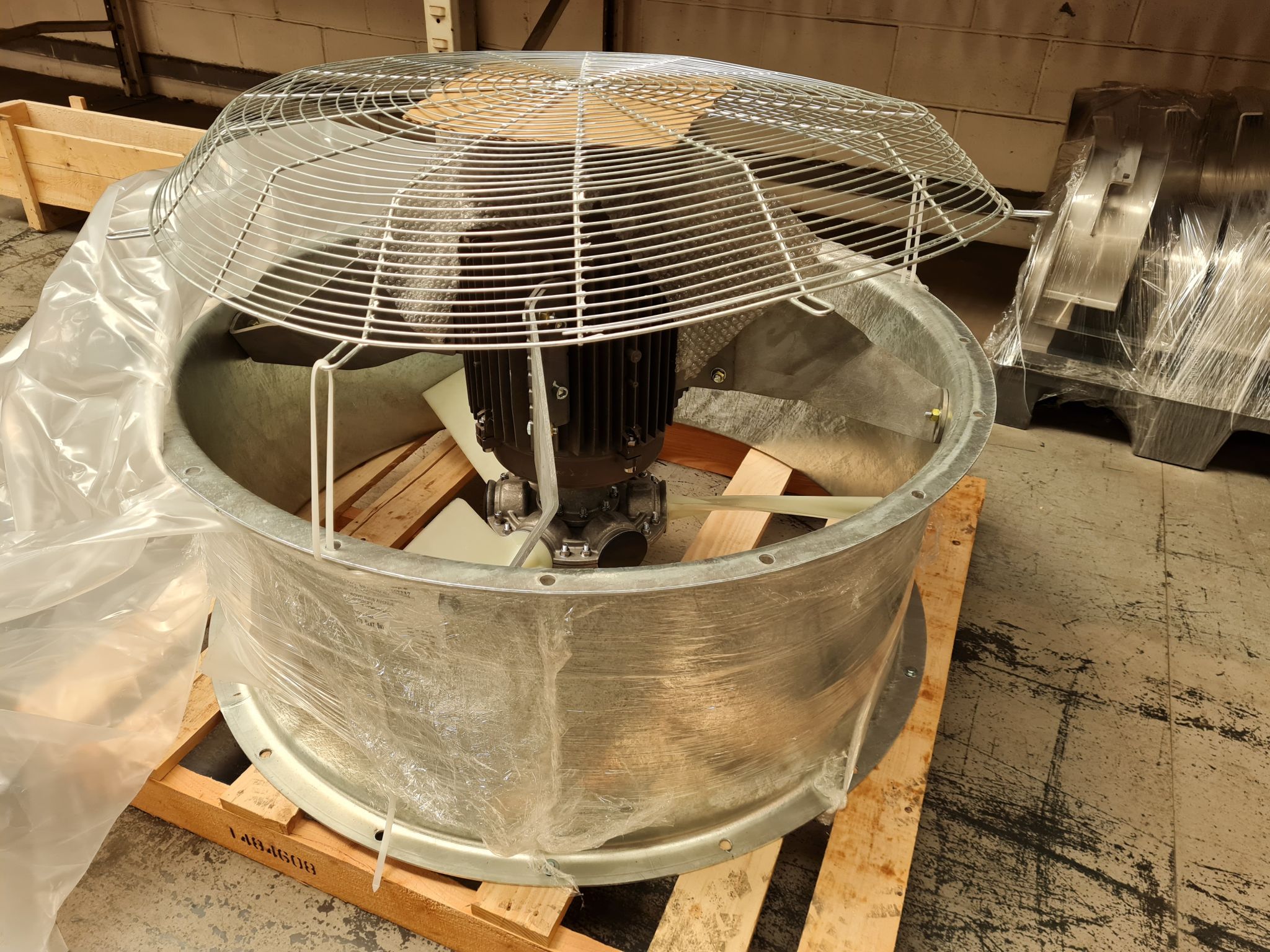

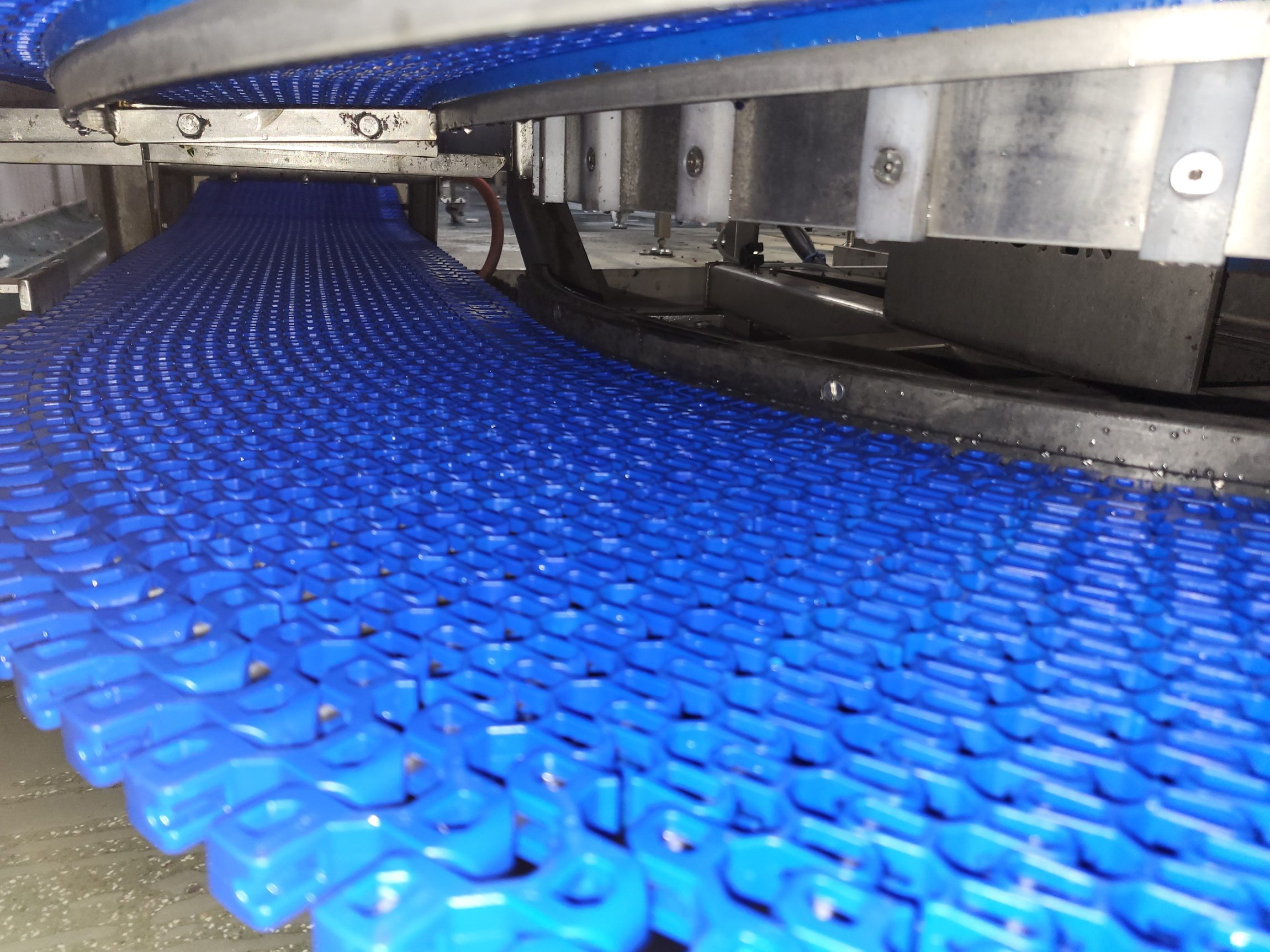

- Belt & Drive System Enhancements – Adjusting belt speed, width, or type to suit new product requirements.

- Airflow & Refrigeration Optimisation – Improving airflow patterns and upgrading evaporators for uniform cooling.

- Control System Upgrades – Integrating modern automation and remote monitoring capabilities.

- Hygiene & Cleaning Enhancements – Implementing enhanced clean-in-place systems and food-grade stainless steel modification.

- Temperature Configuration – Customising temperature settings to suit specific process needs, whether for freezing, chilling, or cooling applications.

- Throughput Capacity Enhancement – Modifying system components to increase product flow rate and maximise processing efficiency.

Seamless Integration

Our expert engineers ensure minimal downtime by efficiently installing modifications with precise planning and execution.

Performance Testing & Optimisation

Once installed, we conduct rigorous testing as part of our commissioning process to verify functionality, efficiency, and hygiene compliance before the system is returned to full operation.

Modification Enquiry

+44 (0)1603 672 455

info@korutek.com

Korutek Engineering Ltd

Centrum, Norwich Research Park,

Norwich, NR4 7UG

Why Choose Korutek?

Decades of Expertise

Backed by over 20 years of experience in freezing and cooling technology.

Customised Solutions

Modifications tailored to your production needs.

Minimal Disruption

Modifications carried out with careful scheduling to avoid production downtime.

Sustainable & Cost-Effective

Enhancing efficiency to reduce operational costs.

Ready to upgrade your spiral system? Contact us today to discuss your modification requirements.

Spiral System Modification Questions

Korutek Engineering Services

Spiral system repairs

Korutek Engineering are the global expert engineers when it comes to spiral cooling and freezing systems.

Spiral system modification

Korutek Engineering work on creating optimised spiral cooling systems for clients all over the world.

Spiral system relocation

We work with food manufacturers all over the world on complex spiral system relocation projects.

Spiral system inspection

We are uniquely qualified to inspect systems for faults and opportunities for optimisation.

Spiral system maintenance

Effective spiral freezer and cooling system maintenance from the global experts at Korutek Engineering

Remote Condition Monitoring

Korutek Remote Condition Monitor helps monitor spiral freezers, coolers and chillers enabling proactive maintenance and reduced downtime.

Spare Parts

Korutek Engineering provide the OEM parts to global food manufacturers required for constant optimal performance.