Maximising Efficiency and Reliability with Korutek’s Freezing and Chilling Innovation

In today’s frozen and chilled food production industry, maintaining the efficiency of freezing and chilling systems is crucial for smooth and reliable operations. As a leader in freezing technology, Korutek provides innovative solutions tailored to meet our clients’ specific demands. Evaporators in our Spiral Freezer and Chillers exemplify our commitment to delivering high-efficiency cooling while minimizing downtime, particularly in environments that require continuous production.

How Evaporators Work

Think of an evaporator as the lungs of your freezing or cooling system. Inside the evaporator is a refrigerant, which absorbs heat very efficiently. As warm air from the food products or the room touches the evaporator, the refrigerant inside soaks up that heat, making the air around it colder. This cold air then circulates in the freezer, keeping everything nice and frozen.

However, as the air passes over the hot products being frozen and returns to the evaporator coil, it carries moisture from the products. This cooling process causes the moisture to condense on the evaporator coils, eventually freezing and forming frost or snow over time..

The Frost Challenge: Moisture Build-up

The frost or snow formation on the evaporator coils, caused by moisture from the hot products, can shorten production hours if not managed properly. When excessive frost accumulates, the evaporator needs to be defrosted to maintain proper airflow and efficient cooling. While this defrosting is a planned process, it can become a consideration if production hours need to be extended.

Our evaporators are specifically selected and designed to run for determined production hours without needing defrosting. At the end of the production shift, the machine is defrosted, ensuring optimal performance without any unplanned interruptions.

Korutek’s Solution: ASRS and Sequential Defrost (SD)

To increase production hours, Korutek freezers and chillers have advanced technologies to manage frost/snow build-up, ensuring that your system keeps running smoothly for extended production hours.

One of the most effective methods to tackle frost accumulation is using the Air Snow Removal system (ASRS). ASRS technology ensures that frost/snow does not hinder evaporator performance by periodically punching pressurised air through the evaporator to clear the snow and frost build-up without interrupting the cooling process, resulting in prolonged production hours.

In addition to ASRS, Korutek offers evaporator systems with Sequential Defrosting (SD) technology, a sophisticated system, with several banks of evaporator coils that defrost individual evaporator units in sequence while maintaining overall cooling operations. This ensures the freezer always has spare capacity, so one evaporator and fan unit can be shut down for defrosting while the others continue operating. This is particularly beneficial for systems which require 24/7 operation to maximize throughput by removing gaps in production. The result is a seamless, uninterrupted workflow that minimizes downtime and improves productivity.

Ongoing Innovation: The Future of Evaporators

At Korutek, we are not stopping there. We are continuously researching new ways to enhance evaporator efficiency. One of our most exciting developments involves exploring new materials and high-tech manufacturing processes. These innovations aim to increase production hours and reduce energy consumption without raising costs. Whilst still in the research phase, the theory has been proven and modelled, this will soon revolutionize the way evaporators manage heat and moisture.

Korutek’s Expertise in Custom Solutions

At Korutek, we understand that no two manufacturing operations are the same. Whether you require large-scale installations or specialized systems, we ensure your freezing and chilling systems meet all regulatory standards, including the tightening of F-gas regulations, while boosting efficiency.

As F-gas regulations become stricter, businesses using freezers or chillers that still rely on F-gases, such as Freons, are required to switch to more environmentally friendly alternatives like natural refrigerants (e.g., CO₂ or ammonia) with lower/ negligible Global Warming Potential (GWP) and Ozone Depletion Potential (ODP). F-gases are potent greenhouse gases, and transitioning to natural refrigerants is critical for both compliance and sustainability.

Korutek’s machines are designed not only to comply with these new regulations but also to improve system capacity and efficiency. Planning to upgrade your freezing or chilling systems to meet the F-Gas requirements is imperative, we can provide tailored solutions to help you make the switch to natural refrigerants seamlessly.

Let’s Work Together

Korutek’s machines are designed to help you optimize your cooling processes, reduce downtime, and achieve greater energy efficiency. Whether you are dealing with shortened production hours, using freezers that are not compliant with current F-gas regulations, or simply wanting to increase the capacity of your current system, our advanced technologies and focus on reliability ensure you stay ahead of the competition.

Let Korutek be your trusted partner in optimizing your freezing, chilling and cooling processes, improving sustainability and ensuring compliance!

Table Of Content

Korutek Engineering Systems

Korutek build spiral freezers and chillers for the biggest food manufacturers around the world. If you’re looking for a team with a global reach that is able to provide industry-leading design and build services, contact Korutek today.

Compact Spiral Series

The Compact Spiral Series, consists of the 300 (CPS300), 450 (CPS450) and the 600 (CPS600) models.

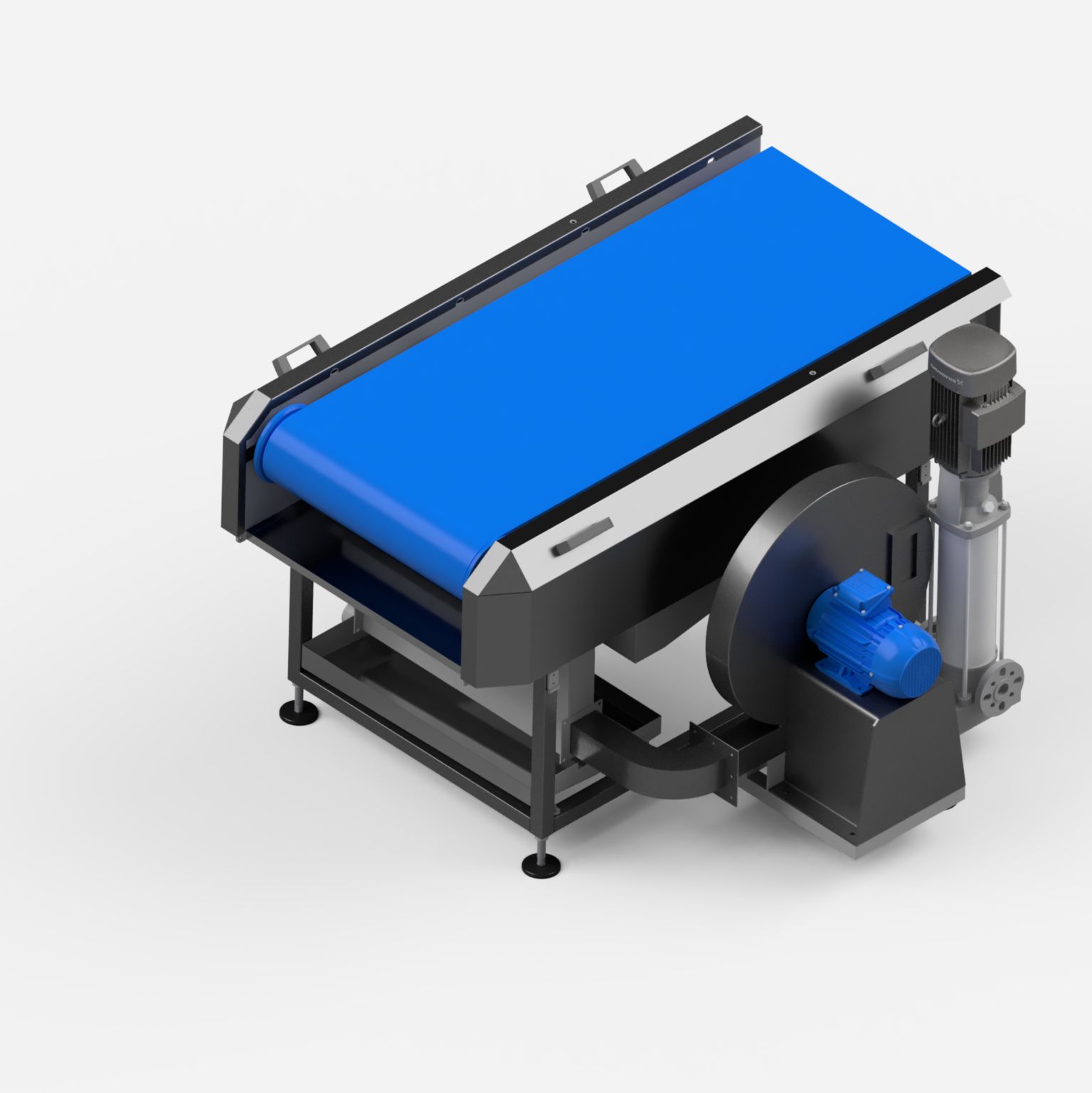

Compact Inline Tunnel

The system operates as one system using one, two or three separate inverter-controlled conveyor belts.

Spiral freezer systems

We are new system specialists, operating and consulting with the largest food industry manufacturers, all over the world.

Spiral chiller systems

Korutek Engineering are new spiral chiller specialists, operating and consulting with the largest food industry manufacturers.

Spiral cooler systems

We are new spiral cooler system specialists, manufacturing for and consulting with global food industry companies.

IQF freezers

We are an IQF freezer specialist, operating and consulting with some of the largest food manufacturers across the world.

Freezer Leasing Solutions

Revolutionise Your Food Production with Korutek's Freezer Leasing Solutions.