Why Replacing Rail/ Belt Support Wear Strips Matters More Than You Think

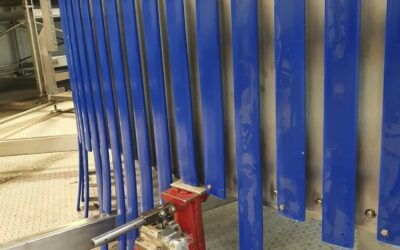

In the realm of spiral freezers and conveyor systems, it's often the smallest components that have the greatest impact. One such critical element hidden from sight is the Rail/ Belt Support Wear Strip. These components are essential to ensure the smooth, efficient,...