Don’t Let Your Gearbox Grind to a Halt: The Crucial Role of Gearbox Oil Replacement in Spiral Freezers

However, even the most robust machines are only as reliable as the care they receive, and gearbox oil plays a key role in keeping operations running smoothly.

The Importance of Gearbox Oil Replacement

Gearbox oil isn’t just a lubricant; it’s the lifeblood of the gearbox. It reduces friction between moving parts, dissipates heat, and protects components from wear and tear. Over time, however, oil degrades. It collects debris, loses viscosity, and ultimately fails to perform its core functions. In spiral freezers, where gearboxes operate in demanding conditions, this degradation happens faster than many anticipate.

This is why gearbox oil should be replaced annually. Delaying this simple yet critical maintenance task can have catastrophic consequences.

How to Spot Gearbox Oil That’s Past Its Prime

Not sure if it’s time to change the oil? Watch for these red flags:

- Increased vibration from the gearbox

- Unusual grinding or humming noises

- Higher operating temperatures

- Oil that looks dark, smells burnt, or feels unusually thick/thin

These are your gearbox’s way of asking for help. Don’t ignore them.

A Real-World Example: When Neglect Becomes Expensive

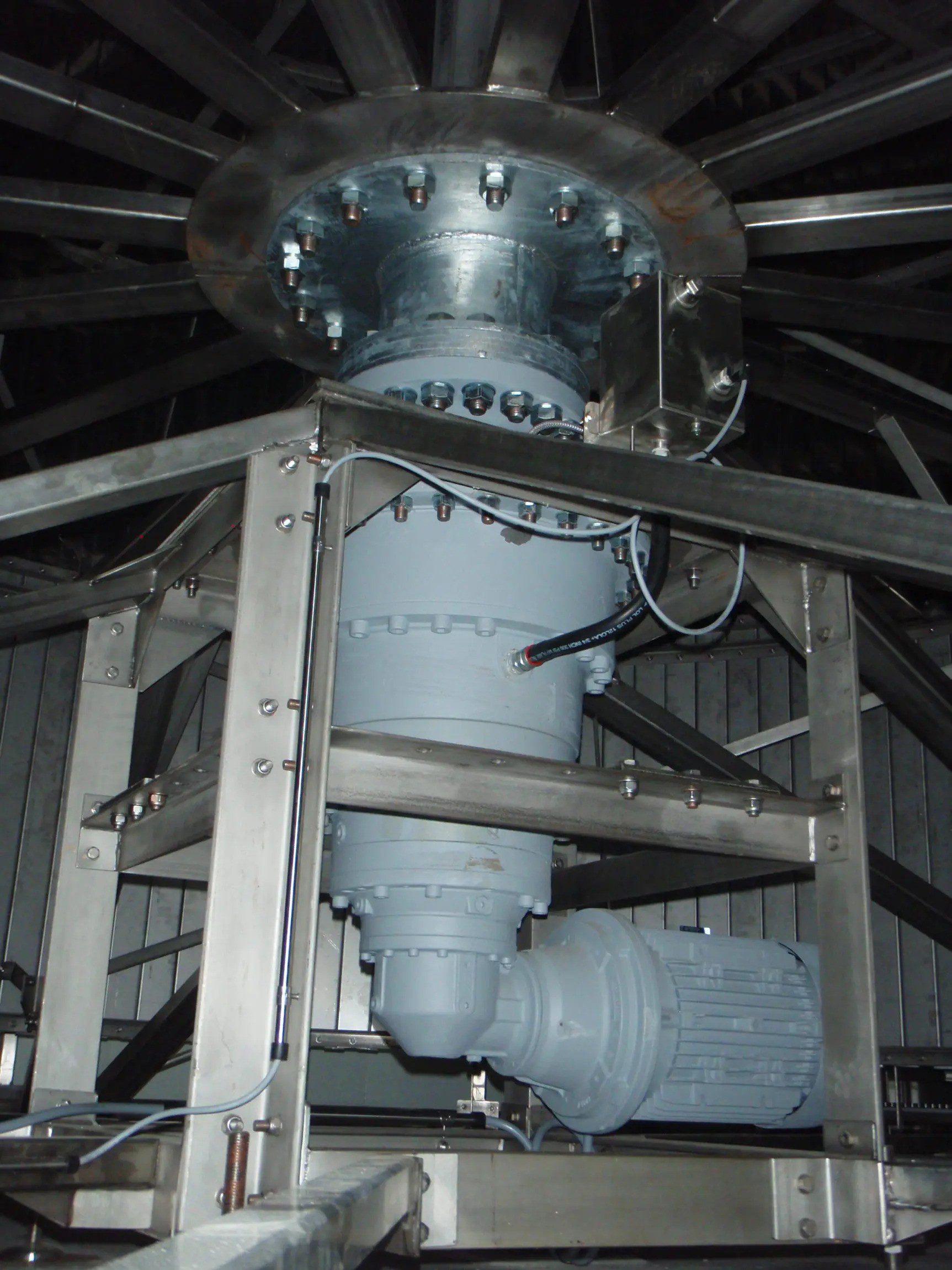

At a meat processing facility, routine maintenance on a spiral freezer was overlooked, specifically the annual replacement of gearbox oil in the drum drive. Over time, the degraded oil lost its lubricating properties, failing to reduce friction between internal components.

As the gearbox continued to operate under these conditions, internal components began grinding against each other, causing increased friction that generated excessive heat and accelerated wear. The heat caused the oil seals to harden and crack, ultimately leading to a loss of oil pressure and visible leakage. With no effective lubrication and falling oil levels, metal components began grinding against each other, compounding the damage.

What began as a minor, neglected maintenance task quickly escalated into a complete unit failure, resulting in unexpected downtime, costly repairs, and potential production losses as the gearbox was destroyed.

Fortunately, the facility had a spare gearbox on hand. Korutek’s service engineers quickly stepped in to replace the damaged unit. The production line was back up and running within a day, but not without cost. The incident served as a harsh reminder of how easily downtime and damage can be avoided through diligent spiral freezer preventive maintenance measures (PPM).

How Korutek Helped

They reached out to us, and Korutek responded quickly. Our engineers went to the site and during the inspection, analysis of the gearbox oil revealed the presence of fine metal particles, indicating that the unit had been operating with degraded oil, resulting in internal wear and mechanical stress.

Our team not only replaced the failed gearbox with the customer’s spare, but also supplied an additional replacement unit with specialised low-temperature coating to help them build inventory resilience. This way, they’re better prepared for the future.

But we didn’t stop there; we also guided them on best practices for maintenance scheduling and strongly recommended the installation of remote condition monitoring sensors across critical assets.

The Role of Predictive Maintenance & Condition Monitoring

This incident could have been entirely preventable with the right predictive maintenance strategy.

Preventive and predictive maintenance are the foundation of smart operations. When you regularly inspect, service, and monitor equipment, you reduce the risk of unexpected failures. But the next level of protection comes from remote condition monitoring sensors.

These sensors detect anomalies in vibration, temperature, and movement, signalling when something isn’t right, often long before a failure occurs. Had such sensors been installed in the spiral freezer’s gearbox, they would have flagged the issue early. Maintenance teams could have acted before damage set in.

Key Takeaways

Replace gearbox oil annually. It’s a small task with a big impact.

Don’t wait for failure. Predictive maintenance and condition monitoring prevent costly downtime.

Inventory matters. Always have critical spares on hand.

Partner with proactive experts. Korutek supports food manufacturers with rapid response services, expert advice, and future-proof solutions.

FAQs

- How often should gearbox oil be checked? Every 3–6 months is ideal for checking oil levels and quality, with full replacement recommended annually.

- What type of oil is best for spiral freezer gearboxes?

Always use manufacturer-recommended synthetic or semi-synthetic oils designed for low-temperature, high-load applications. - Can I extend the interval beyond one year?

Not advised. The operational environment of spiral freezers accelerates oil degradation. Annual replacement is the safe bet. - Are there industry standards for gearbox maintenance?

Yes, most manufacturers and regulatory bodies recommend annual oil changes and ongoing condition monitoring for critical assets. - How do I start with condition monitoring?

Start by identifying critical assets, installing vibration and temperature sensors (remote condition monitoring), and integrating data with your maintenance system. Korutek can help you with the setup.

In Conclusion

A gearbox failure can be a costly setback, but it doesn’t have to happen. Annual oil changes, predictive maintenance, and smart planning are the best ways to keep your spiral freezer (and production line) running smoothly. At Korutek, we don’t just fix problems, we help you prevent them.

Table Of Content

Korutek Engineering Systems

Korutek build spiral freezers and chillers for the biggest food manufacturers around the world. If you’re looking for a team with a global reach that is able to provide industry-leading design and build services, contact Korutek today.

Compact Spiral Series

The Compact Spiral Series, consists of the 300 (CPS300), 450 (CPS450) and the 600 (CPS600) models.

Compact Inline Tunnel

The system operates as one system using one, two or three separate inverter-controlled conveyor belts.

Spiral freezer systems

We are new system specialists, operating and consulting with the largest food industry manufacturers, all over the world.

Spiral chiller systems

Korutek Engineering are new spiral chiller specialists, operating and consulting with the largest food industry manufacturers.

Spiral cooler systems

We are new spiral cooler system specialists, manufacturing for and consulting with global food industry companies.

IQF freezers

We are an IQF freezer specialist, operating and consulting with some of the largest food manufacturers across the world.

Freezer Leasing Solutions

Revolutionise Your Food Production with Korutek's Freezer Leasing Solutions.