Why Replacing Rail/ Belt Support Wear Strips Matters More Than You Think

In the realm of spiral freezers and conveyor systems, it’s often the smallest components that have the greatest impact. One such critical element hidden from sight is the Rail/ Belt Support Wear Strip. These components are essential to ensure the smooth, efficient, and reliable operation of your belt system.

When they start to wear down, the consequences extend far beyond increased noise —it’s the first domino in a chain of mechanical problems that can shut down your entire production line. Though they may appear to be simple plastic or composite guides, their function is vital. Overlooking their maintenance can lead to significant operational disruptions and costly unplanned downtime.

What Are Rail/ Belt Support Wear Strips?

The Role They Play in Spiral Freezer Systems

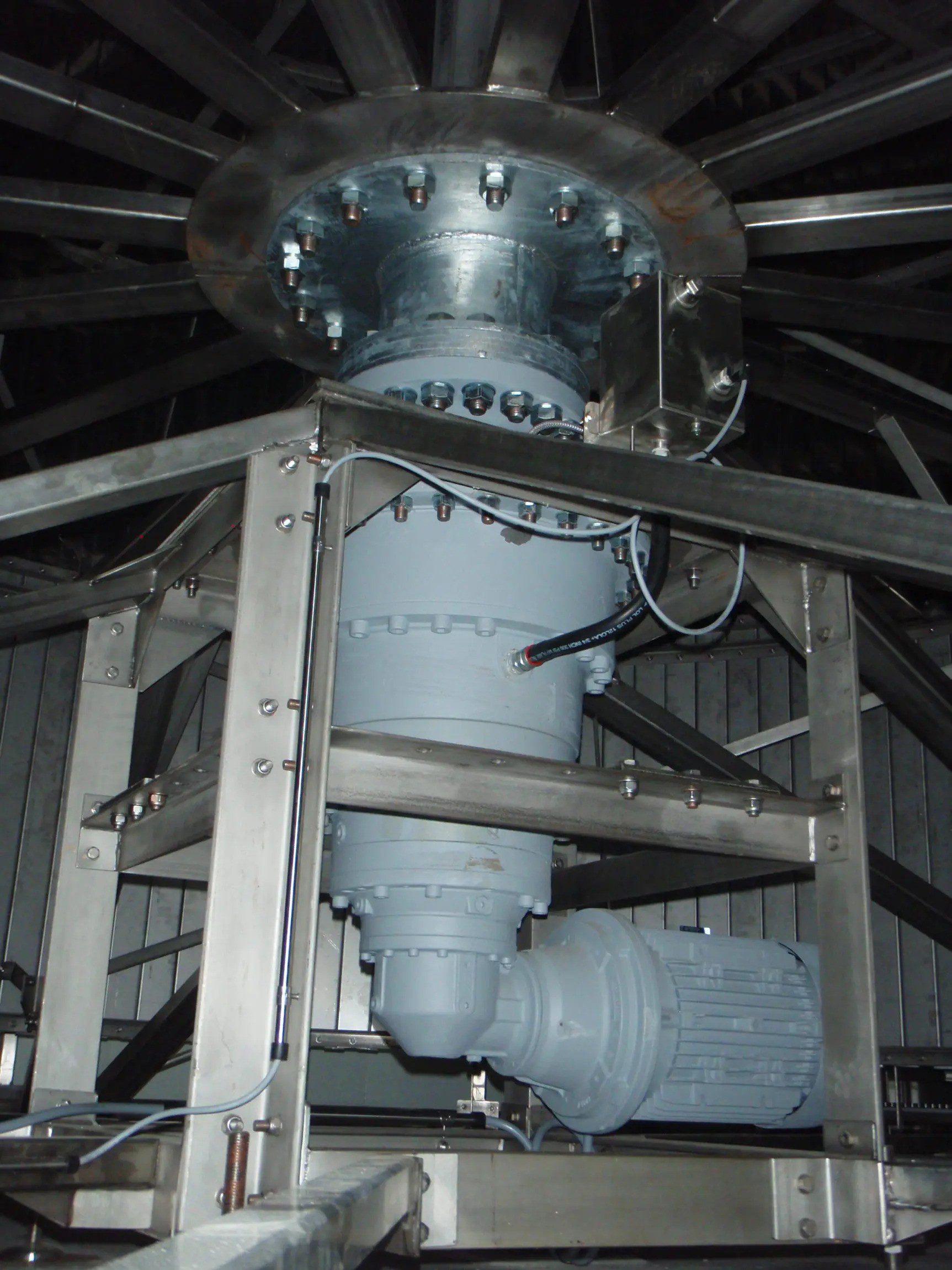

Rail/ Belt Support Wear Strips are fixed components designed to support and guide the spiral conveyor belt throughout its movement inside the freezing chamber. Think of them as the rails on a train track—they keep everything in line and moving smoothly.

How They Guide and Stabilise the Belt During Operation

These wear strips reduce friction and the chances of metal rubbing against metal, which can otherwise cause mechanical wear. They allow the belt to glide cleanly along the belt support structure and protect both the belt and the machine housing from direct contact, which could cause serious wear or deformation over time.

What Happens When Rail/ Belt Support Wear Strips Wear Out?

Common Signs of Wear and Tear

- Frayed or misaligned belt edges.

- Irregular belt movement.

- Increased noise during operation.

- Visible thinning or cracking of the wear strip.

Consequences of Ignoring Replacement

Reduced Efficiency and Belt Misalignment

As the wear strips degrade, the belt may start to misalign from its path, leading to uneven freezing, product inconsistencies, inefficient movement and even Christmas tree effect that stops down production.

Accelerated Belt Damage and Emergency Breakdowns

Worn strips mean direct contact between the belt and metal structure, leading to increased friction, premature belt wear, and potential sudden breakdowns that can halt operations altogether.

Chain Reaction: How Other Components Get Affected

It’s not just the belt that suffers. Misalignment can place stress on sprockets, bearings, auxiliary drive motors, and the spiral structure, amplifying repair costs exponentially.

Real-World Scenario:

Failure to Replace Wear Strips in Time

A major bakery producer running multiple spiral freezers 20 hours a day started noticing slight inconsistencies in their belt’s movement. Production wasn’t affected—yet—but maintenance logs flagged wear strip erosion. They thought of replacing this along with the other freezers’ wear strip replacement.

The Breakdown: Belt Drift, System Shutdown, and Costly Repairs

Ignoring the warning signs, the plant delayed replacing the strips. Within weeks, the belt began to drift severely, misaligning products, causing uneven freezing, and finally, a complete system shutdown due to a snapped spiral belt.

Engineers later found that the worn strips had allowed the belt to cut into the rail, damaging the rail support arms.

The Ripple Effect: Downtime, Production Loss, and Frustration

In total, the plant faced:

- Lengthy unplanned production downtime.

- Lost production due to inconsistent freezing.

- Frustration and loss of reputation from clients expecting timely deliveries.

How Korutek Rescued the Operation

Swift Diagnosis and Professional On-Site Inspection

Korutek responded within hours, conducting a full inspection. The team diagnosed not only worn wear strips but also secondary damage to the belt and rail support arms.

Precision Replacement of Wear Strips and Belt Realignment

Using premium-grade, long-lasting wear strips, Korutek’s engineers performed a complete belt support wear strip replacement, patched in the new spiral belt, replaced sprockets and realigned the spiral belt to ensure perfect path tracking.

Results: Restored Efficiency, Extended Equipment Life

The outcome? The spiral freezer now runs quieter, smoother, and more energy-efficiently than before. Most importantly, the preventive maintenance now avoids costly surprises.

When and How Often Should You Replace Wear Strips?

Korutek’s Recommended Maintenance Schedule

To prevent breakdowns like this, Korutek recommends replacing Rail/Belt Support Wear Strips every two years, or earlier if you notice signs of wear. High-usage environments may require quarterly checks.

Early Detection Tips for Plant Managers and Engineers

- Use a flashlight to inspect the wear strip edges

- Check for belt marks or metal shavings nearby

- Listen for unusual sounds during operation

- Schedule quarterly maintenance evaluations

FAQs – About Rail/ Belt Support Wear Strips

What materials are used in wear strips?

Most are made from Food Grade UHMWPE 1000, low-friction plastics designed to withstand low temperatures and resist abrasion.

Can I inspect the wear strips without disassembling the belt?

Yes, visual checks from access panels often reveal signs of wear or misalignment. Routine inspection is key.

How much does it cost to replace worn wear strips?

It varies by model and freezer size, but replacement costs are far less than emergency belt or motor repairs.

What tools or expertise do I need to replace them?

You’ll need standard mechanical tools, but expertise is vital. Improper installation can lead to misalignment. Korutek offers full-service replacements.

Can worn wear strips void my equipment warranty?

Yes, many manufacturers require proper wear strip maintenance as part of their warranty terms. Ignoring them may leave you uncovered.

Where can I find replacement parts or service help?

You can contact Korutek for high-quality parts and on-site services from certified technicians and engineers.

Conclusion: Don’t Let Small Parts Cause Big Problems

Replacing Rail/ Belt Support Wear Strips might not seem urgent until it emerges as a sudden problem. As we’ve seen, ignoring this simple maintenance task can lead to a chain reaction of failures and serious costs. With a trusted partner like Korutek, you can stay ahead of the curve and protect your spiral freezing system from expensive unplanned downtime.

Table Of Content

Korutek Engineering Systems

Korutek build spiral freezers and chillers for the biggest food manufacturers around the world. If you’re looking for a team with a global reach that is able to provide industry-leading design and build services, contact Korutek today.

Compact Spiral Series

The Compact Spiral Series, consists of the 300 (CPS300), 450 (CPS450) and the 600 (CPS600) models.

Compact Inline Tunnel

The system operates as one system using one, two or three separate inverter-controlled conveyor belts.

Spiral freezer systems

We are new system specialists, operating and consulting with the largest food industry manufacturers, all over the world.

Spiral chiller systems

Korutek Engineering are new spiral chiller specialists, operating and consulting with the largest food industry manufacturers.

Spiral cooler systems

We are new spiral cooler system specialists, manufacturing for and consulting with global food industry companies.

IQF freezers

We are an IQF freezer specialist, operating and consulting with some of the largest food manufacturers across the world.

Freezer Leasing Solutions

Revolutionise Your Food Production with Korutek's Freezer Leasing Solutions.