Case Study: Restoring Life to a Legacy Spiral Freezer for the UK’s Largest Cheese Manufacturer

Introduction

In the world of food manufacturing, downtime can mean the difference between profit and loss. So when the UK’s largest cheese producer faced trouble with their spiral freezer, they needed a partner they could trust. That’s when Korutek Engineering stepped in, known for solving the toughest refrigeration and freezing challenges.

This is the story of how Korutek’s engineers brought an ageing spiral freezer back to life, overcoming every obstacle with sheer determination and precision.

Understanding the Project

The cheese manufacturer’s facility runs around the clock, freezing massive batches of cheese before packaging. At the heart of this operation stood a decades-old spiral machine. It had served well over the years, but time and temperature fluctuations had taken their toll.

From Cooler to Freezer: A Machine’s Journey

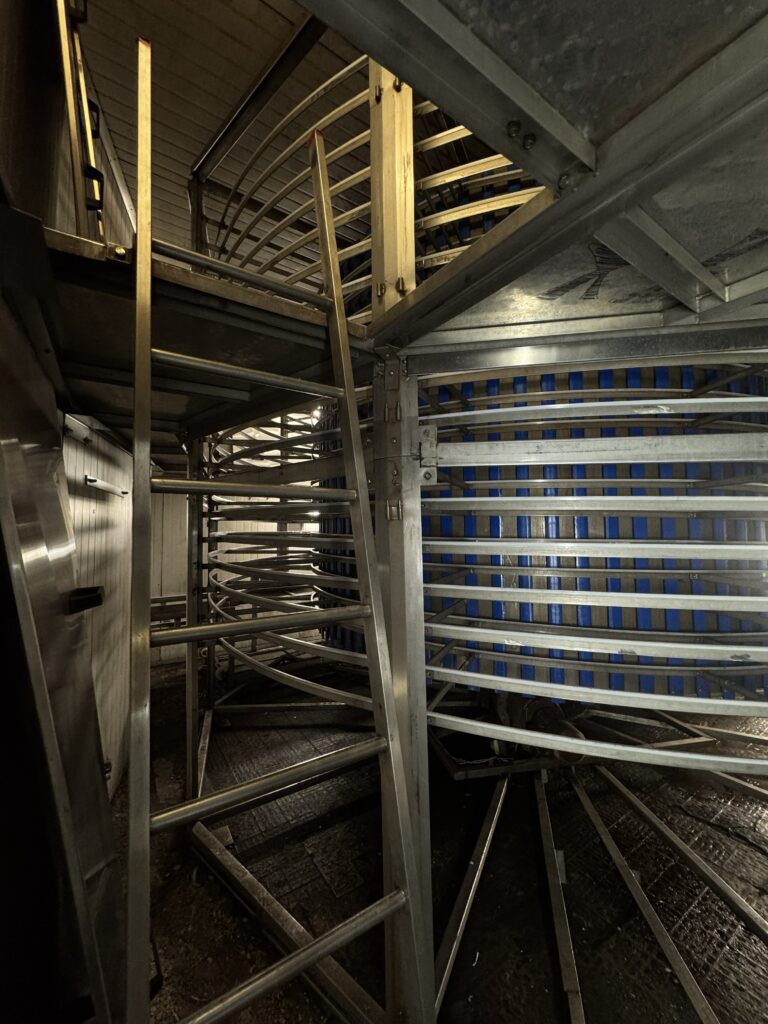

Originally designed as a spiral cooler, the unit was later converted into a spiral freezer to meet higher production demands. The conversion was successful, but not without issues. The temperature extremes caused the tiled floor to crack and break, creating structural and hygiene challenges that only worsened with age.

After years of continuous use, the freezer started showing clear signs of fatigue: worn-out belts, damaged rollers, and obsolete parts. The drum was out of alignment, causing uneven tension on the belt. The manufacturer knew that the machine wouldn’t survive another production cycle without expert intervention.

Korutek Steps In

When the factory manager called Korutek, the team already had a history with this machine. Months earlier, Korutek engineers had rectified the shape of the drum, successfully bringing the freezer back into operation. But this time, the issue ran deeper—the entire spiral belt needed replacement.

The Belt Replacement Challenge

Replacing a belt on a double-drum spiral freezer is no small task. The belt is the lifeline of the machine, guiding and carrying thousands of kilograms of product daily. Over time, it had stretched, twisted, and become unsafe. The manager’s quick decision to have it replaced saved the machine from complete breakdown.

Planning the Approach

Before a single bolt was touched, the team carefully mapped out the process—removal, containment, replacement, testing. Every move was designed to minimise disruption while keeping the site spotless.

Step One: Removing the Old Belt

The engineers began by methodically removing the old belt, placing every section into custom wooden containers to avoid contamination. Despite limited access and fragile flooring, they worked with precision. Within 1.5 days, the belt was safely removed, debris cleared, and the site was ready for installation.

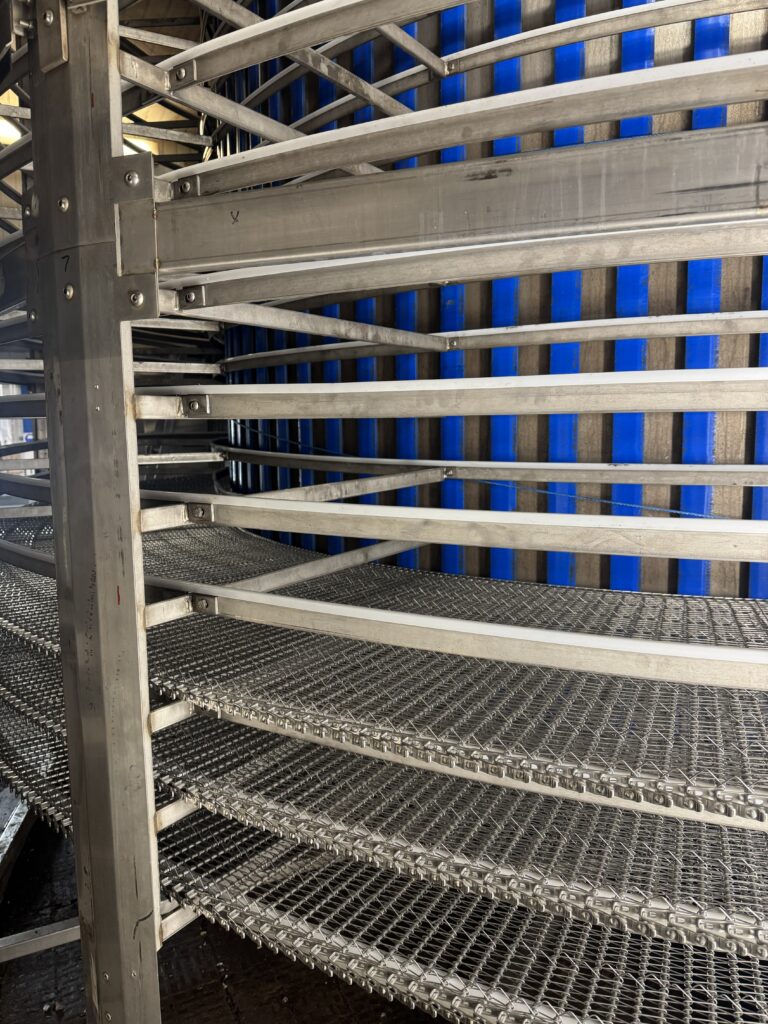

Step Two: Replacing Wear Strips and Rollers

Once the belt was out, it was time to strip the rail wear strips and rollers, both heavily worn out. Being a double-drum spiral, everything had to be done twice – meticulous, repetitive, and slow work. But Korutek’s engineers handled it smoothly, knowing that these components would define the new belt’s performance.

Over another 1.5 days, the team replaced every roller and carefully aligned new wear strips on the support rails, ensuring the structure was ready for the fresh belt.

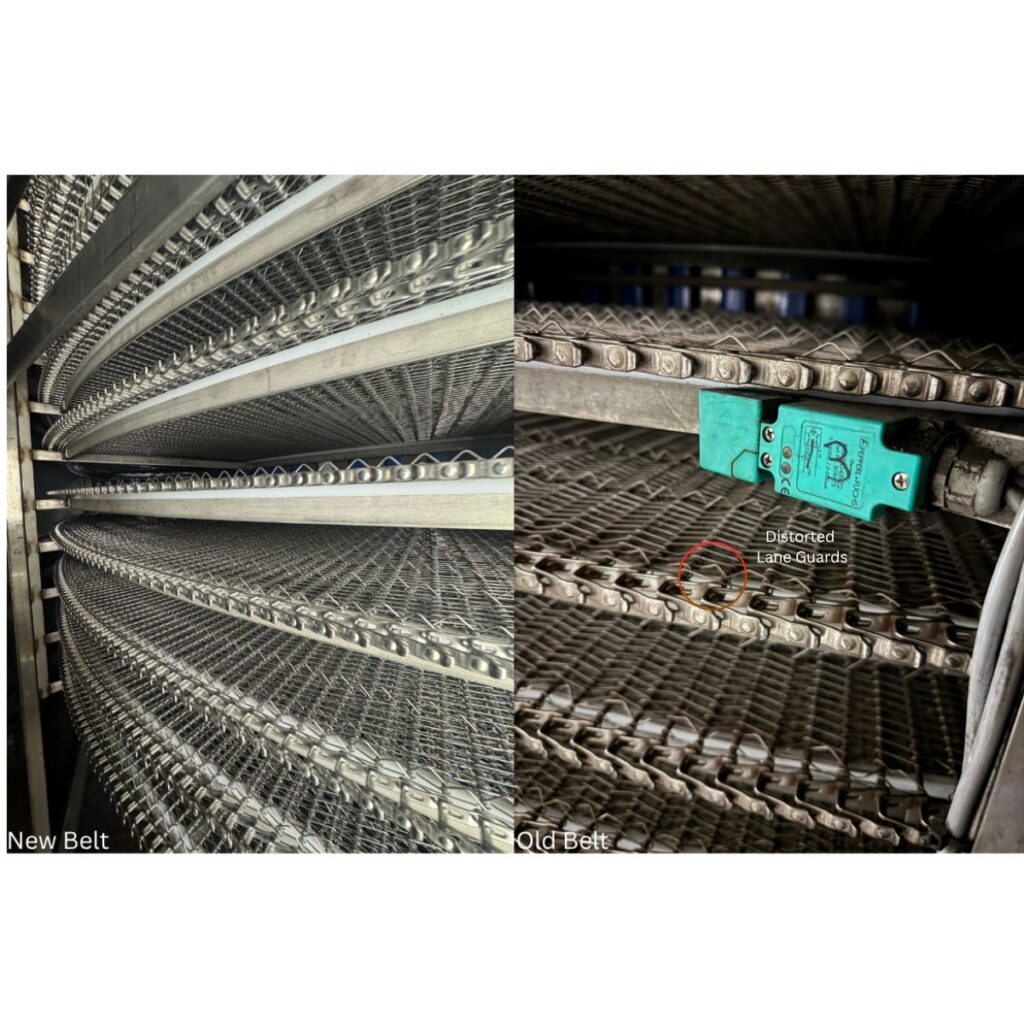

Step Three: Installing the New Belt

The new belt arrived – but there was a catch. It came in small rolls, each covering only half a tier. That meant constant splicing and jointing to make one continuous loop. It was painstaking, stop-and-start work that demanded patience and precision. After long hours, the team finally pieced the sections into one seamless belt.

When they loaded it onto the new wear strips and rollers, the machine looked brand new.

Overcoming the Cold Challenge

But the story didn’t end there. Once the refrigeration kicked in, the belt began to contract sharply under -40°C temperatures. Korutek’s engineers instantly recognised the issue; the belt needed extra length to handle contraction safely. Without hesitation, they got back to work, adding a small extension that ensured smooth movement even under extreme cold.

This extra effort prevented future belt tension issues and proved Korutek’s commitment to perfection.

Final Testing and Results

With the new belt fitted and the tension corrected, the engineers ran the final test. The spiral ran perfectly. No slippage, no abnormal sounds—just a clean, smooth operation. The factory ran a product test, and the results were spot on. The freezer was back in full swing, ready for years of reliable service.

Outcome and Customer Satisfaction

By the end of the project, the machine was almost unrecognisable. From a worn-out relic to a shining, fully functional spiral freezer, it was a complete transformation. The customer was thrilled, not only with the outcome but also with the professionalism and care shown throughout the process.

They’ve since named Korutek their go-to engineering team for all future maintenance and breakdowns – a partnership built on trust and proven performance.

Lessons from the Project

What this project showed is simple: even an ageing machine can be given a second life when handled by the right people. Korutek’s mix of technical skill, adaptability, and attention to hygiene set a benchmark for how engineering in food production should be done.

Conclusion

This wasn’t just a repair; it was a revival. Through strategy, teamwork, and grit, Korutek extended the life of a critical spiral freezer by a number of years. For the client, that meant reliability and peace of mind. For Korutek, it reaffirmed what they do best: turning engineering challenges into success stories.

FAQs

- How long did the entire spiral freezer restoration take?

The full process, from removing the old belt to final testing, took roughly 4-5 days, completed with minimal disruption to production. - Why did the belt need to be replaced?

Years of wear and temperature stress had stretched and weakened it, making replacement essential for safety and performance. - What challenges were faced during the project?

Limited access, fragile flooring, obsolete parts, and cold contraction at -40°C made the work complex—but all were resolved expertly. - How did Korutek maintain hygiene during the process?

Every waste component was contained in wooden crates, and the site was kept spotless to meet strict food industry standards. - What was the result for the client?

A fully restored, efficient spiral freezer with extended lifespan, reduced maintenance needs, and renewed trust in Korutek’s engineering team.

Table Of Content

Korutek Engineering Systems

Korutek build spiral freezers and chillers for the biggest food manufacturers around the world. If you’re looking for a team with a global reach that is able to provide industry-leading design and build services, contact Korutek today.

Compact Spiral Series

The Compact Spiral Series, consists of the 300 (CPS300), 450 (CPS450) and the 600 (CPS600) models.

Compact Inline Tunnel

The system operates as one system using one, two or three separate inverter-controlled conveyor belts.

Spiral freezer systems

We are new system specialists, operating and consulting with the largest food industry manufacturers, all over the world.

Spiral chiller systems

Korutek Engineering are new spiral chiller specialists, operating and consulting with the largest food industry manufacturers.

Spiral cooler systems

We are new spiral cooler system specialists, manufacturing for and consulting with global food industry companies.

IQF freezers

We are an IQF freezer specialist, operating and consulting with some of the largest food manufacturers across the world.

Freezer Leasing Solutions

Revolutionise Your Food Production with Korutek's Freezer Leasing Solutions.