Why Replacing Rail Wear Strips on Time Matters: A Real Case from a UK Food Manufacturer

In food production, small components rarely get attention until something goes wrong. Rail wear strips are one such component. They sit quietly beneath a conveyor belt, doing one simple job: reducing friction and keeping the belt properly supported.

When they deteriorate, the consequences are rarely dramatic at first. They are subtle. And that’s what makes them dangerous.

Here’s what happened on a recent project.

The Problem: Fine Metallic Residue on Finished Product

A major UK food manufacturer contacted us after noticing a fine, dark metallic residue on their product and on the floor beneath their spiral freezer. It wasn’t part of the recipe. It wasn’t coming from the packaging. Quality checks began raising concerns.

At first, they reviewed the obvious variables. Ingredients. Handling. Cleaning procedures. Everything appeared normal.

But the presence of this residue created a serious risk. Any visible contamination can lead to rejected batches, retailer scrutiny, and reputational damage. In large-scale food production, even a minor anomaly can quickly become expensive.

That’s when they called us in.

The Investigation: What Was Really Happening

After a full inspection of the double drum spiral freezer, our team identified the root cause.

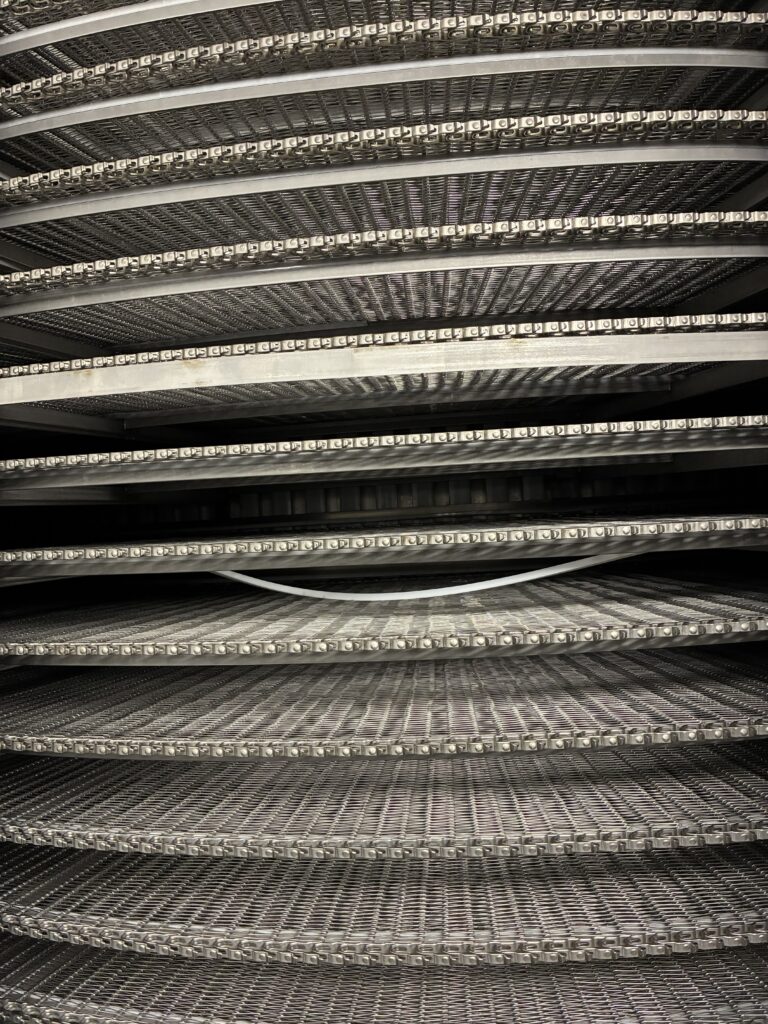

The stainless steel conveyor belt was grinding against the belt support rails in multiple locations. The rail/belt support wear strips — designed to create a low-friction surface between the belt and the rail — had deteriorated significantly in certain sections.

With the belt support wear strips worn down, the belt began making direct contact with the stainless steel rails.

Metal on metal.

That contact generated extremely fine stainless steel particles — essentially metallic dust — which were dispersing onto the product and the surrounding area.

Nothing had “broken” in the conventional sense. The machine was still running. But the protective buffer layer had failed, and the consequences were quietly building.

The Solution: A Labour-Intensive but Necessary Repair

The fix was straightforward in theory. Replace the wear strips.

In practice, it was far from simple.

This was a large double drum spiral freezer. To replace the rail wear strips correctly, we had to remove the entire conveyor belt assembly. That meant careful dismantling, handling, and reinstallation — all carried out with precision to avoid alignment issues later.

Both drums required full rail wear strip replacement. While we were there, we also completed minor corrective work on the support rails to ensure improved belt stability and long-term performance.

It was a demanding process. But once completed, the machine returned to smooth operation. No friction points. No metallic residue. No quality concerns.

The Lesson: Wear Doesn’t Announce Itself

Here’s the key takeaway.

Mechanical deterioration rarely announces itself with a loud failure. It builds gradually. Friction increases. Tolerances shift. Surfaces wear down. And eventually, symptoms appear — often in places you don’t expect, like on finished food products.

In this case, the issue didn’t begin as contamination. It began as delayed maintenance.

Waiting for a visible failure can mean the problem has already escalated. Preventative rail wear strip replacement is far less disruptive than dealing with product recalls, rejected pallets, or retailer audits.

Why Proactive Replacement Protects Your Brand

Timely rail wear strip replacement:

- Prevents metal-to-metal contact

- Reduces friction and belt stress

- Minimises contamination risk

- Extends conveyor and rail lifespan

- Protects product quality and retailer relationships

In food manufacturing, quality is not negotiable. And often, it depends on components that few people see.

Are Your Wear Strips Due for Inspection?

If your spiral freezer or conveyor system hasn’t been inspected recently, it may be worth taking a closer look. Rail or belt support wear strips do not last indefinitely, and deterioration can occur unevenly.

A simple inspection can determine whether replacement is due — before friction turns into contamination.

If you would like us to assess your system, get in touch to book an inspection.

Table Of Content

Korutek Engineering Systems

Korutek build spiral freezers and chillers for the biggest food manufacturers around the world. If you’re looking for a team with a global reach that is able to provide industry-leading design and build services, contact Korutek today.

Compact Spiral Series

The Compact Spiral Series, consists of the 300 (CPS300), 450 (CPS450) and the 600 (CPS600) models.

Compact Inline Tunnel

The system operates as one system using one, two or three separate inverter-controlled conveyor belts.

Spiral freezer systems

We are new system specialists, operating and consulting with the largest food industry manufacturers, all over the world.

Spiral chiller systems

Korutek Engineering are new spiral chiller specialists, operating and consulting with the largest food industry manufacturers.

Spiral cooler systems

We are new spiral cooler system specialists, manufacturing for and consulting with global food industry companies.

IQF freezers

We are an IQF freezer specialist, operating and consulting with some of the largest food manufacturers across the world.

Freezer Leasing Solutions

Revolutionise Your Food Production with Korutek's Freezer Leasing Solutions.