Site use Korutek’s spiral freezer to reach desired temperature for their products like sausages, rolls, buns etc.

As a supplier of spiral Freezer, Korutek Engineering was asked for the:

- Replacement of Cracked Drive Adapter and oil seal.

- Replacement of Gear box oil.

- Replacement of Gear box oil level sensor.

Replacement of Cracked Drive Adapter & Oil Seal:

Power was isolated to ensure work safety. Restrictions were faced to access beneath the Drum as it was a confined Space. Moreover work areas were slippery due to leaked oil from gearbox. At first Drum was dismantled from Drive by untightening bolts. The task was appeared as almost unachievable due to rust in bolts thread and slippery tools. Drum was made uplift with Hydrauliic Jack and whole weight of drum was kept upon axle stand. Cracked drive adapter was moved out of its place with the help of chiesel,hammer,clover, Jack. New drive adaptor was installed. Then Drum was fixed with drive again. Later, Machine was checked and turned it to operation.

Replacement of Gear box oil:

Old oil was drained through drain plug and Oil storage tank was filled with new oil.

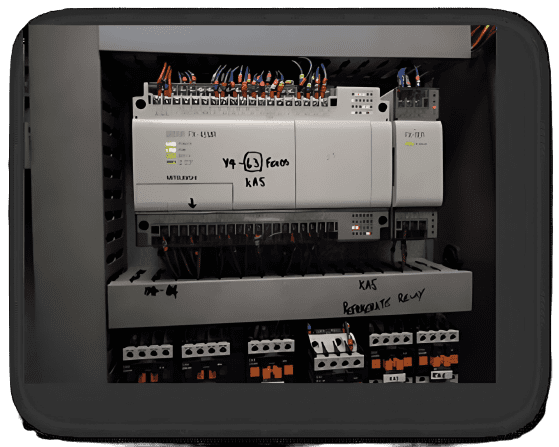

Replacement of Gear box oil level sensor:

Control panel’s power was isolated. Old sensor with terminal block was replaced.

Fixes or Recommendations:

- Metal Crack was observed in welding connection between central pole of Drum and Flange. (See below). There is possibility of Pole break down as well as Drum’s break down as Drum’s weight is fully carried by this Pole. Needs urgent replacement for long term service.

- Gear box oil needs to be changed periodically as per instruction.

Conclusion:

The Site was contractor friendly. Induction program regarding health and safety were arranged. Work safety was ensured by Site contact and some additional tools were provided with us by site contact for the easiness of Job. However, it was a good experience with our old machine and the customer.